Equally suited to manual and automated applications, plasma offers many advantages in producing miniature and precision welds, high-volume strip metal joining, and equipment assembly.

Since its introduction to the welding industry in 1964, plasma welding has expanded on its original advantages of control and accuracy by producing high-quality welds with long electrode life in high-production applications. Now, plasma is being used to weld everything from precision surgical instruments and weld kitchen equipment for the food industry, to repairing jet engine blades.

The plasma is actually a gas that is heated to an extremely high temperature and ionized so that it becomes electrically conductive. Similar to GTAW (gas tungsten arc welding), the plasma arc welding process uses this plasma to transfer an electric arc to the workpiece. The metal to be welded is melted by the intense heat of the arc and fuses together. Metals hat can be welded using plasma include: stainless, heat-resistant, and other steels; titanium; Inconel; Kovar; zircalloy; tantalum; copper; brass; gold; and silver.

|

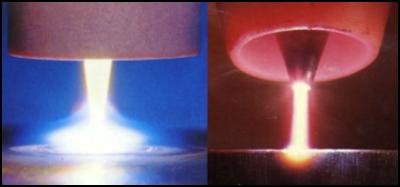

| A comparison of the TIG/GTAW (left) and Plasma (right) welding arcs. |

In the plasma welding torch a tungsten electrode is located within a copper nozzle that has a small opening at the tip. A pilot arc is initiated between the torch electrode and the nozzle tip; and the arc is then transferred to the metal to be welded. By forcing the plasma gas and arc through a constricted orifice, the torch delivers a high concentration of heat to a small area. With this process, high-performance plasma welding equipment is able to produce exceptionally high-quality welds. The protected electrode is less exposed to contamination, especially when welding materials that tend to outgas when heated. This results in longer electrode life and increased time between electrode maintenance (usually one eight-hour shift).

Plasma gases are normally argon; and the torch also uses a secondary gas (argon, argon/hydrogen or helium) to assist in shielding the molten weld puddle, which minimizes oxidation of the weld. The nozzle orifice is selected to control arc diameter, with assists in predicting the weld bead size. Additional equipment required for plasma welding includes: a power supply; a plasma console (external or built-in); a water recirculator (external or built-in); and plasma welding torch and accessory kit (tips, ceramics, collets, and electrode set-up gages).

The plasma arc starting and transfer is gentle and consistent, which is an advantage in welding thin sheet materials, fine wires, and miniature parts. The arc length, shape, and heat distribution make the welding standoff distance less critical than with GTAW; no AVC (automatic voltage control) is needed in nearly all applications. High stability during welding reduces arc wandering and enables the operator to use an arc-starting tool in close proximity to the weld joint for optimum heat sinking. The arc energy density is about three times that of GTAW, which reduces weld distortion and the heat-affected zone, makes smaller welds possible, and enables higher weld speeds (with welds completed in as little as 0.005 seconds).

Starting currents of less than 1.0 Amp enable precision welding of miniature components and good control in down sloping to a weld edge. Once the pilot arc is started, plasma power supplies generate minimal high-frequency noise, enabling plasma to be used with NC (numerical control) equipment without electrical interference. This also allows the use of plasma welding in such applications as hermetic sealing of electronic components, unlike GTAW arc welding where electrical disturbances would possibly damage sensitive internal electronic components. Plasma supplies also offer a wide range of frequency options for pulsing applications, sometimes as high as 10 kHz.

| Arc energy density is about three times that of GTAW |

Other plasma welding applications are many and varied. An entire repair industry has grown from using plasma in die and mold repair. The ability of micro-arc supplies to start a low-current arc and repair slight nicks and dents from misuse or wear has provided an effective alternative to conventional repair and heat treatment. For outside edges the plasma process offers greater arc stability and requires less skill in controlling the weld puddle. To reach inside corners and crevices, the tungsten electrode of the GTAW/TIG process can be extended to provide improved access.

In strip metal welding the plasma process is consistent in transferring the arc to the workpiece and working up to the edges of the weld joint. In automated applications no arc distance control is needed for long welds, and the process requires less maintenance to the torch components. Tube mills produce tube and pipe by roll forming strip material and welding the mating edges at a weld station. The output of the tube mill depends on the arc welding speed and total time spent at the welding station. The characteristics of the plasma welding process give it a significant advantage in this application, namely: maximum tube mill weld speed; arc stability for optimum weld quality and consistency; and maximum electrode tip life.

www.pro-fusiononline.com

No comments:

Post a Comment