High-quality electrode materials with exact tip geometry tolerances offer a noticeable difference in precision at the arc to produce higher-quality welds with much longer electrode life. One supplier of these products and services is Pro-Fusion, a new company founded by Bernard Mannion and Jack Heinzman III in Newbury Park, CA.

|

| Pro-Fusion, a new company in Newbury Park, CA, is offering the technology and services to use specialty electrode materials with pre-ground electrode tips to enhance precision arc welding. |

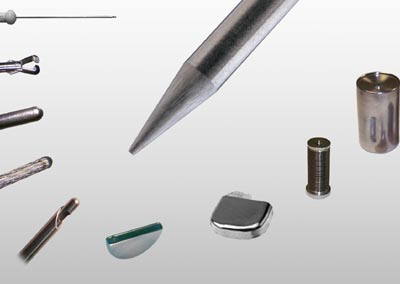

Their new company will begin by offering preground welding electrodes, tungsten electrode grinders, several tungsten alternatives, and a new line of plasma welding torches. Pro-Fusion also offers job shop welding services and precision machine shop services.

Pro-Fusion's customer, J&J Precision of Thomaston, CT, offers contract welding that can involve sealing the ends of small tube diameters. J&J makes eyelets and performs stamping, forming, machining, grinding, and assembly of precision metal components.

J&J's owner, John Maxwell, investigated the latest arc welding technology not as a joining, but as a heating and sealing, procedure. By using precision preground electrodes with a micro-arc welding system, Maxwell was able to seal the tube by momentarily imposing a welding arc on its ending. This melted the tube and produced a smooth hemispherical surface. The preground electrodes ensure accuracy and repeatability, according to Pro-Fusion. J&J uses the same technology for rod and wire end rounding, welding of custom endings to tubes, and creation of ball endings on wire.

Other applications for pre-ground electrodes include repetitive welds on identical parts, quality or critical-function welds, and parts with significant accumulated value prior to welding.

www.pro-fusiononline.com

No comments:

Post a Comment